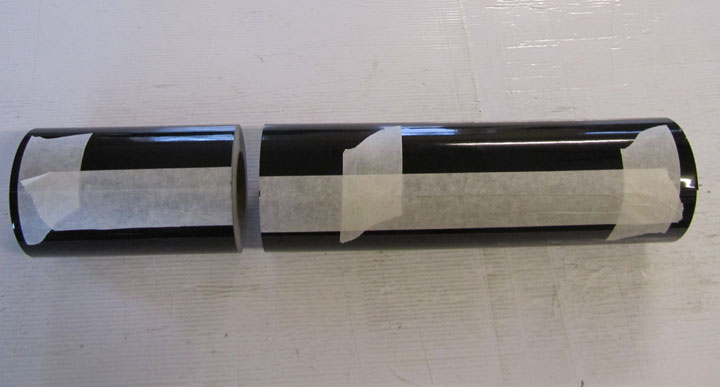

Vinyl Graphics rolls often arrive at your shop or location blotchy, streaked or mottled. Here is what has happened. Sign vinyl has an adhesive coating which is protected by a paper backing. When vinyl is rolled up, the face or glossy surface of the vinyl comes in contact with the paper backing. The paper creates in imprint on the vinyl making it blotchy or mottled. This does not always happen and is normally only clearly visible on black rolls. It has been my observation that this is more prevalent on rolls that are tightly wound thus creating more pressure between the vinyl and the paper backing. I have also noticed that when you get a blotchy or mottled roll it is going to be that way for the entire roll.

Vinyl Graphics rolls often arrive at your shop or location blotchy, streaked or mottled. Here is what has happened. Sign vinyl has an adhesive coating which is protected by a paper backing. When vinyl is rolled up, the face or glossy surface of the vinyl comes in contact with the paper backing. The paper creates in imprint on the vinyl making it blotchy or mottled. This does not always happen and is normally only clearly visible on black rolls. It has been my observation that this is more prevalent on rolls that are tightly wound thus creating more pressure between the vinyl and the paper backing. I have also noticed that when you get a blotchy or mottled roll it is going to be that way for the entire roll.

First, let me say that the vinyl is in no way ruined or unusable. It is simply a cosmetic problem. You can take a piece of mottled or blotchy sign vinyl and lay it in direct sun and in 5 minutes it will be perfectly glossy. You can also take a hair dryer and remove the blotches with heat. Lastly, you can roll up some vinyl and heat it in a microwave. You have to be careful when doing this as too many seconds in a microwave will melt the vinyl or start a fire.

For obvious reasons, when we cut designs in black that will be shipped to a customer we like to remove the blotchiness in advance. A hair dryer was too slow and laying the material in the sun or in a microwave also had several downsides. For this reason, I created a simple process that removes the mottling fairly quickly.

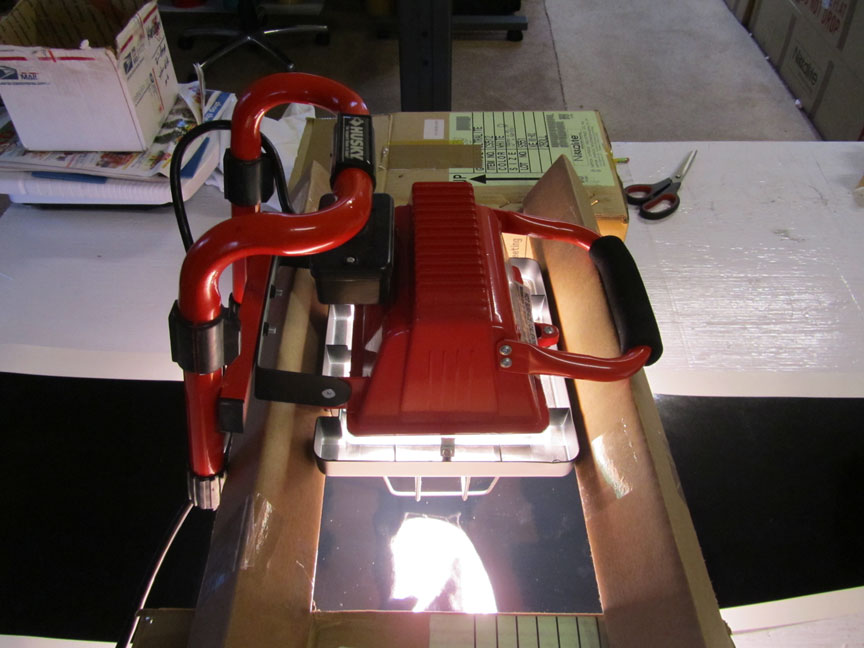

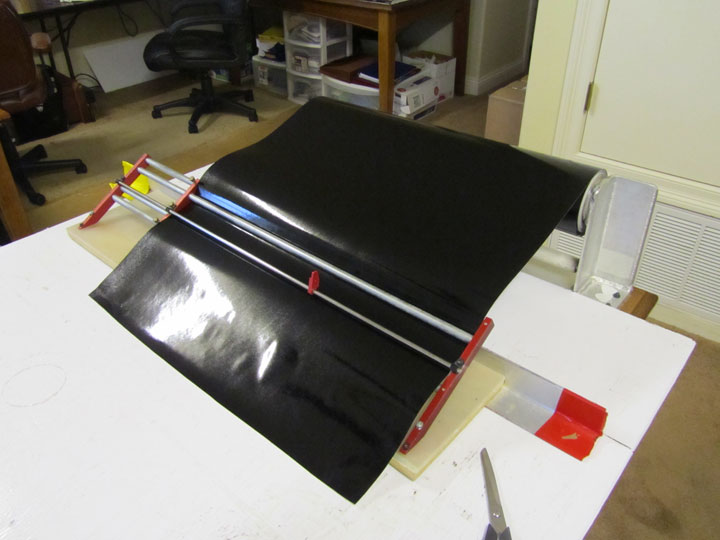

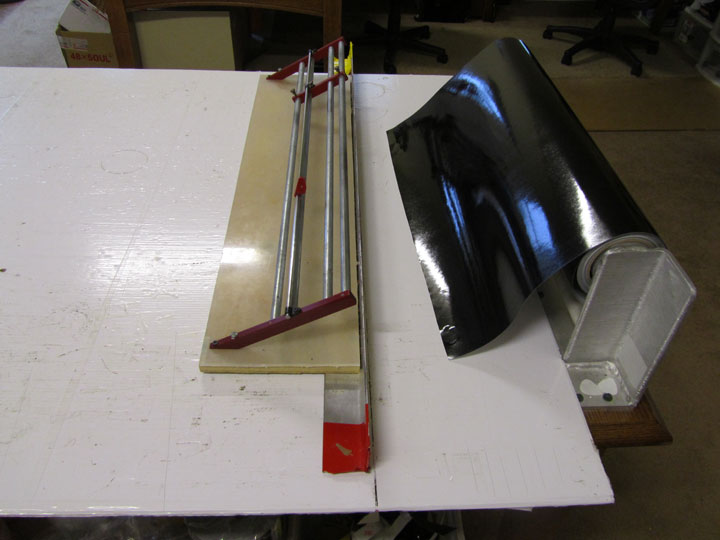

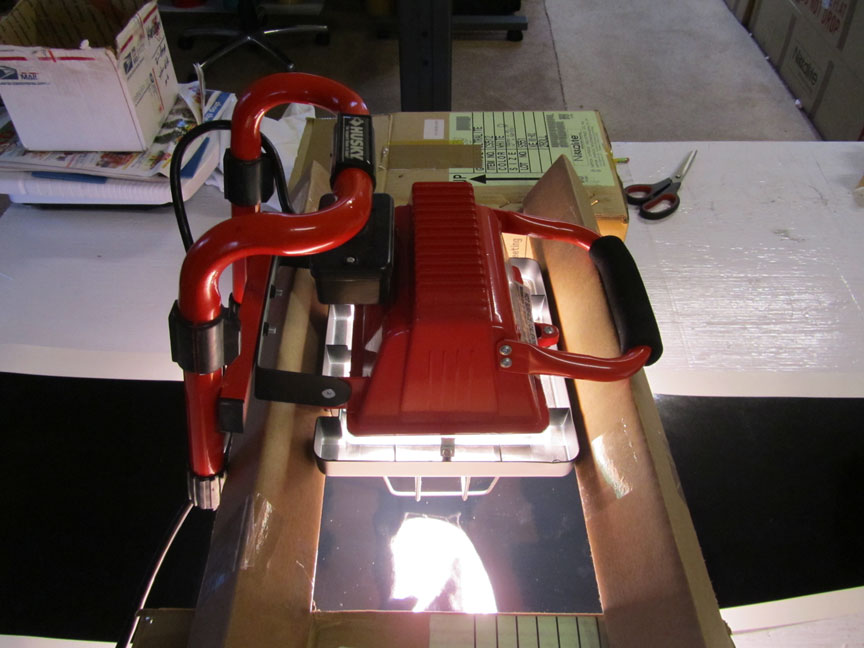

First, I took a couple of boxes and created a support system that would hold a portable halogen lamp. The support system keeps the lamp several inches from the surface below. To heat the vinyl I just set up the system, turn on the lamp and begin sliding the vinyl underneath the lamp. Once the lamp is hot it only takes a few seconds per inch to remove the streaking on the vinyl and gloss it back up. The pictures below show the process.